Chemical Engineering UB Develops Redox Flow Battery Components from Banana Peels

By 2020, renewable energy is predicted to supply 12% of electricity needs in the USA and 20% in Europe. This encourages the advancement of large-scale and stable storage of electrical energy technology, that is battery.

Batteries that are commonly used as energy storage devices for renewable energy power plants are lithium ion (Li-ion) batteries.

This battery is commonly chosen because it has a high energy density and low self-discharge.

Unfortunately the cost required is quite large and the Li-ion battery is facing a crisis in the availability of its constituent materials, especially lithium.

In addition, the energy and power of the Li-ion battery is very limited in battery size.

Considering these facts, three Chemical Engineering students, Faculty of Engineering UB, initiated an innovation of a renewable energy storage device for power plants that has never been applied in Indonesia, namely the Redox Flow Battery (RFB).

The three of them are Moch Hanif Baktitar, Fatin Septianingsih, and Anggita Adiningrum under the guidance of Ir. Bambang Ismulyanto M.S.

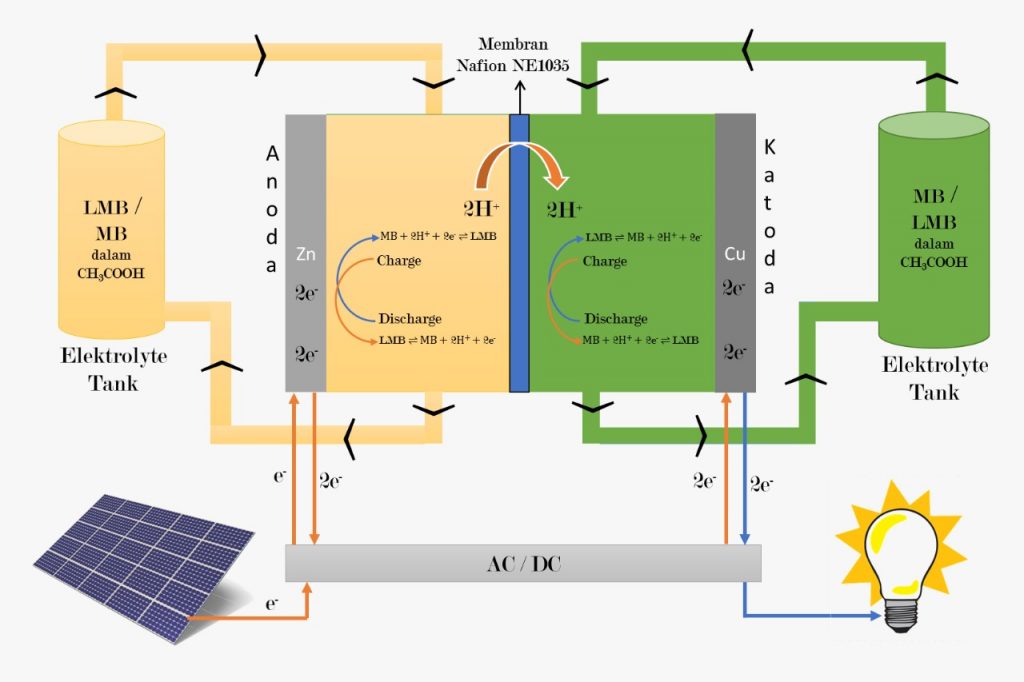

Redox Flow Battery (RFB) is an electrochemical system where electrical energy is stored in two solutions consisting of different redox pairs.

The advantages of this RFB include; able to store energy on a medium to large scale, has the ability to separate energy and power capacity, long life, simple thermal management and maintenance, safe, and low energy density.

In addition, RFB is one type of battery that is reliable and is able to store energy longer than other types of batteries.

The RFB application that has been developed is the Vanadium Redox Battery (VRB). This type of RFB has been used to store electrical energy from renewable electricity sources on a large scale.

The developed countries of the world have developed this type. One of them is China.

This Panda Curtain country has created the largest Vanadium Redox Flow Battery in the world with a capacity of 200MW/800MWh.

However, in its development, VRB requires high installation costs due to the expensive vanadium metal and Nafion membrane, and vanadium which has high corosity.

Therefore, it is necessary to develop RFB with safer electrolyte active ingredients, namely organic redox active ingredients to exploit their chemical potential and to reduce installation costs.

Methylene blue (MB) is a basic dye that is often used in the textile industry as a dye for leather, cloth, silk, cotton, and tannins, and in the paint industry because of its economical price and easy access.

In RFB, Methylene Blue (MB) acts as anolite while Leuco Methylene Blue (LMB) acts as catholite.

In addition, this team also used banana peels as an electrolyte solution to replace strong acids such as H2SO4 because it has a high mineral content such as potassium chloride.

“With the modification of Methylene Blue as an active ingredient and banana peel as an electrolyte liquid, of course it will be a renewable idea to replace the active ingredients and electrolytes that have been developed so far, namely Vanadium in H2SO4 on Redox Flow Battery,” concluded Hanif representing the team. (mic)